We make your ideas a success! In this article, we show how we manage projects from the first client contact to installation - ensuring measurable results every time.

How projects with esto work

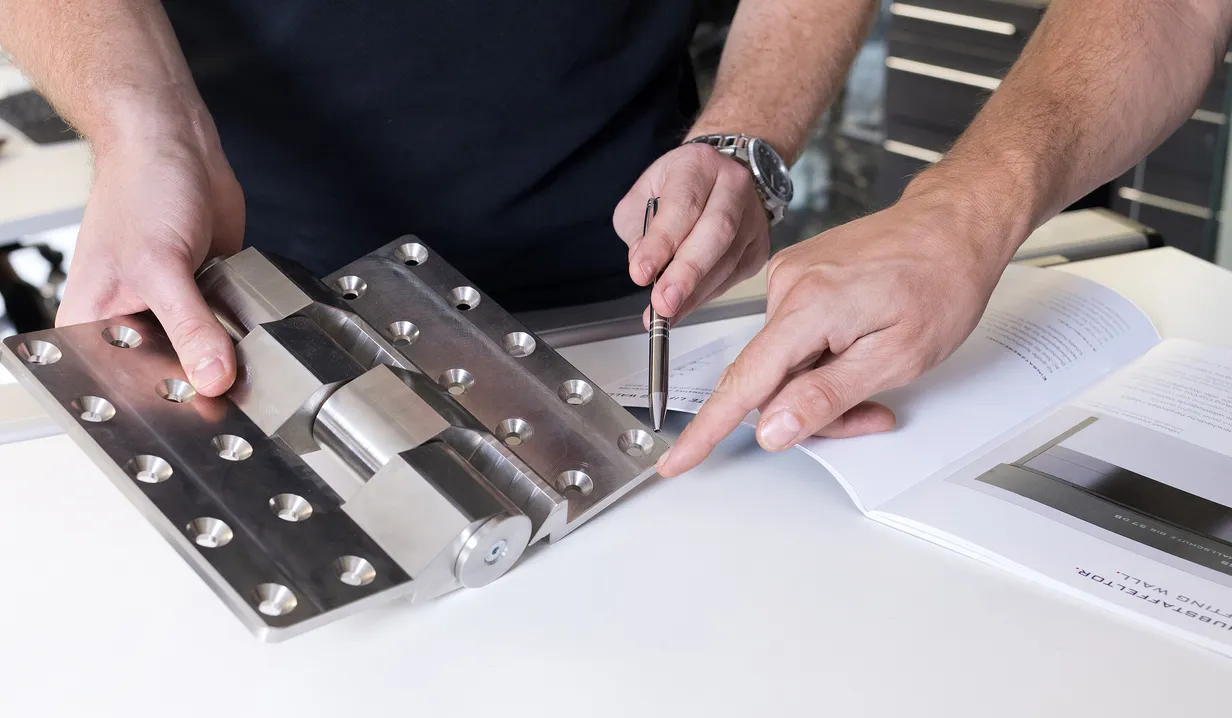

At the start, we assess the feasibility of the request based on our technical expertise. We calculate time, resources and relevant standards to deliver solutions that perfectly meet the project requirements. Once the order is confirmed, our project management team prepares the drawings with all technical specifications so that production can begin seamlessly.

Central to this is the requirements specification jointly developed with the client. This defines dimensions, materials, and - in the case of gates - factors such as speed or noise levels. We also consider the operating environment: temperature, wind, humidity and other conditions are all taken into account during system design. Then the planning phase begins: first, a functional concept is created, followed by space planning for all components, before moving on to detailed engineering. Before production begins, a structural and static verification is carried out. We ensure that all forces are perfectly balanced - a key step for safety and durability - and obtain final client approval.

Material selection follows the criteria defined in the specification sheet, such as safety, wind load, wear resistance, aesthetics and design. Examples: In coastal projects, duplex material is used due to the salty air; bullet-resistant systems follow entirely different standards; for ultra-quiet installations, special materials and configurations are applied. When choosing suppliers, uncompromising quality and reliable, on-time delivery are decisive. We prefer to work with trusted partners who share our commitment to excellence.

In production, all drawings are available, and incoming materials undergo strict quality checks before fabrication begins. The production team coordinates closely with project management and, if required, requests additional information directly from the client. We keep our customers continuously updated on project status - as these are almost always complex, tailor-made solutions.

We secure quality through meticulous planning, detailed component design, and usually through the creation of a prototype. Simulations provide valuable insights but never replace real-world testing. The prototype demonstrates whether everything functions as intended and gives the client a solid first impression. If changes are desired, they are implemented until full approval is granted. Afterwards, serial or final production begins, ensuring timely delivery to the installation site so assembly can start without delay.

We deliver worldwide - to destinations including London, Florida, Saudi Arabia, Hong Kong, the Netherlands, Nevada, parts of Africa and many regions. If confidentiality is requested, client identities remain undisclosed: technology, expertise and project details stay strictly confidential. A few selected references may be shared; most projects remain discreet - often true VIP assignments in the sense of “very important project.”

In the end, it’s not just about satisfaction: our clients are delighted - and return with new, often even more ambitious ideas. If you have any questions or wish to challenge us with an exceptional project, write to info@esto-innovation.eu.

Would you also like to benefit from our experience?

Schedule a non-binding consultation with our experts now. Together, we will identify the first possibilities for the optimum implementation of your project.